- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

LED Fly Killer Housing

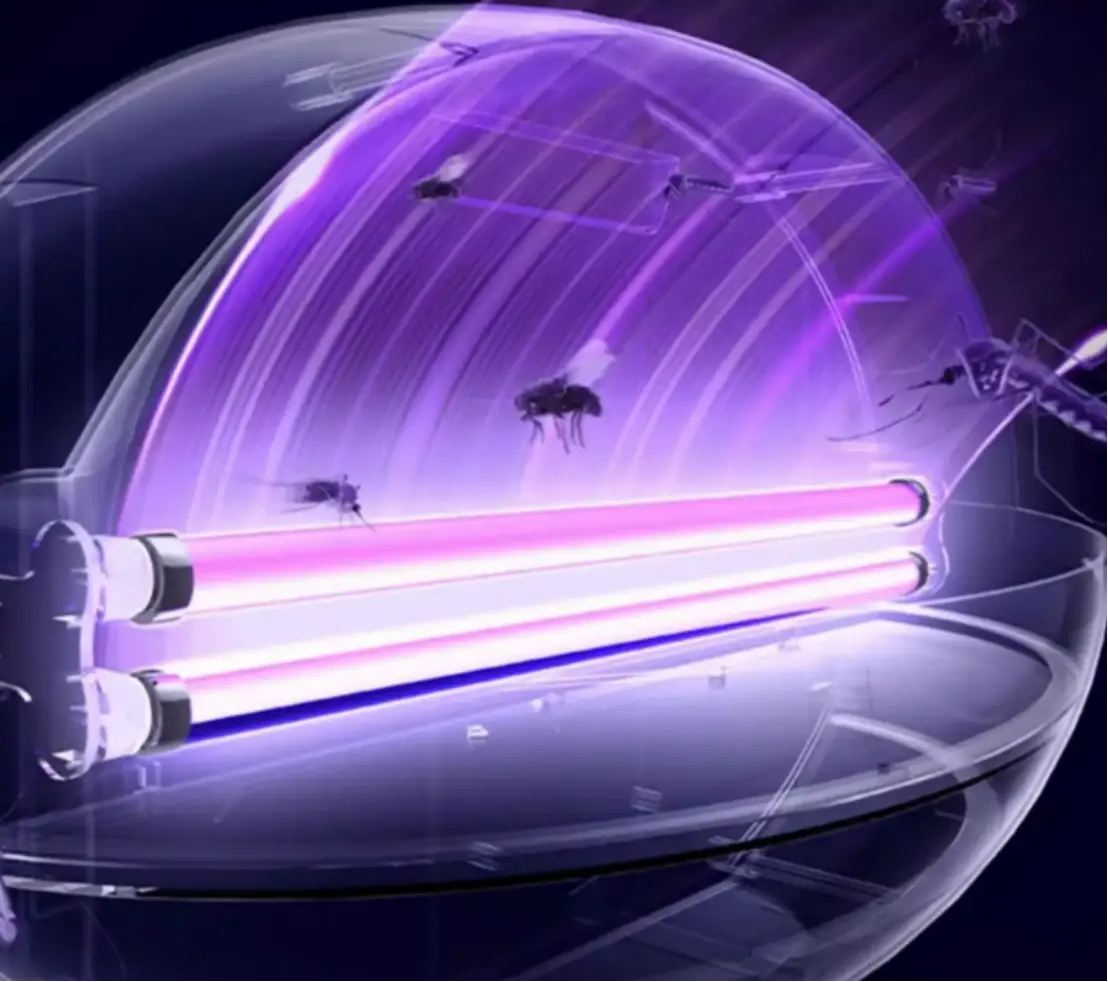

With the improvement of living standards and the increasing demands placed on their living environment, the demand for LED fly killers has also been growing in recent years. However, there are few manufacturers specializing in the production of LED fly killer housings, leading to limited understanding of this field. JE, a manufacturer specializing in LED tube housings in China, currently collaborates with many professional LED fly killer manufacturers to customize LED fly killer housings. If you require professional LED fly killer housing solutions, please contact us.

Send Inquiry

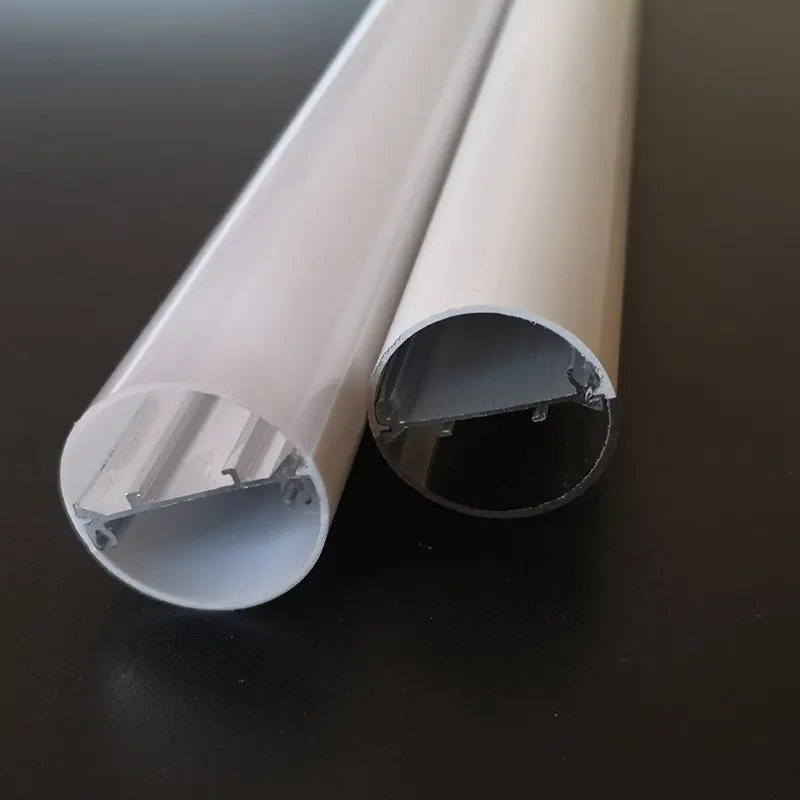

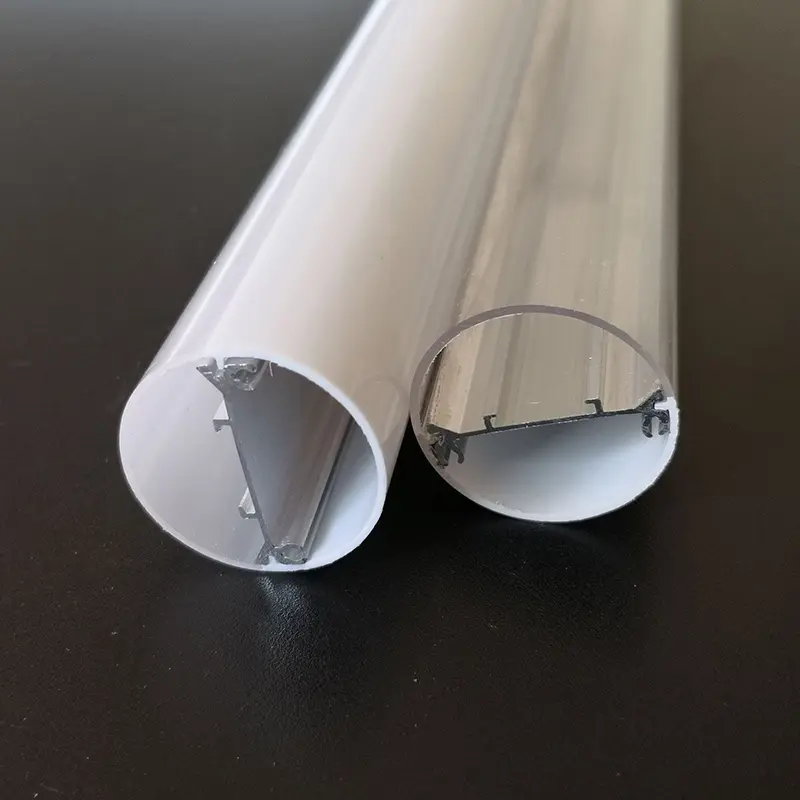

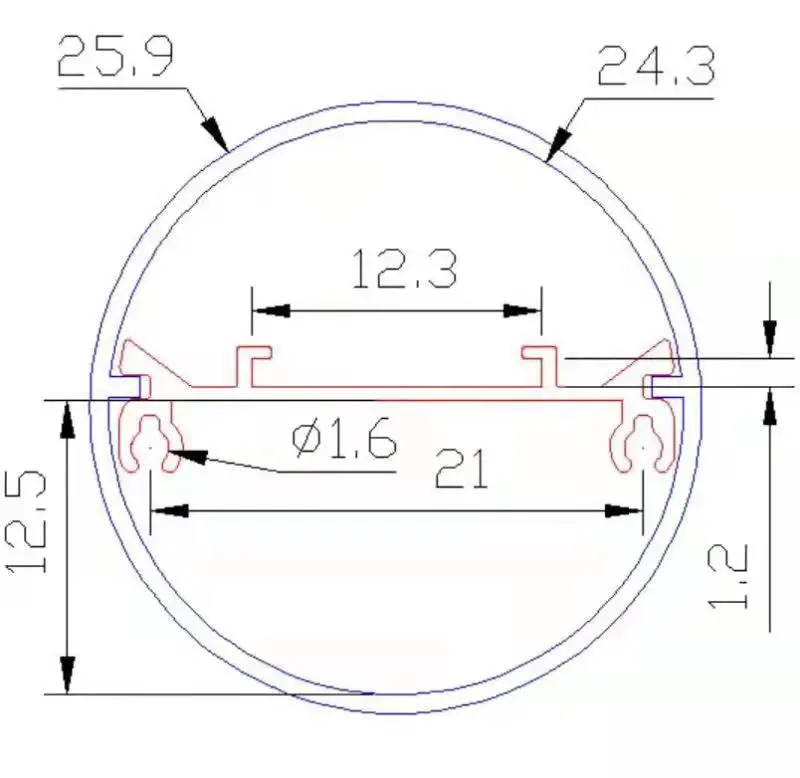

The JE-27 is a standard plastic T8 LED tube housing from our company. Its distinctive feature is its all-plastic housing, divided into two sections: a white bottom, non-luminous portion, and a light-emitting portion available in either opalescent or transparent colors. The tube is internally constructed with aluminum extrusions, accommodating PCBs up to 12 x 1 mm. If this size is suitable for your existing LED fly killer project, we can provide a professional LED fly killer housing solution based on its design. This design ensures that 365nm UVA light can properly penetrate the diffuser while also preventing the housing from yellowing.

Product Parameter (Specification)

| Length | 600mm, 900mm, 1200mm, 1500mm, 2400mm or customized |

| Tube | T8 |

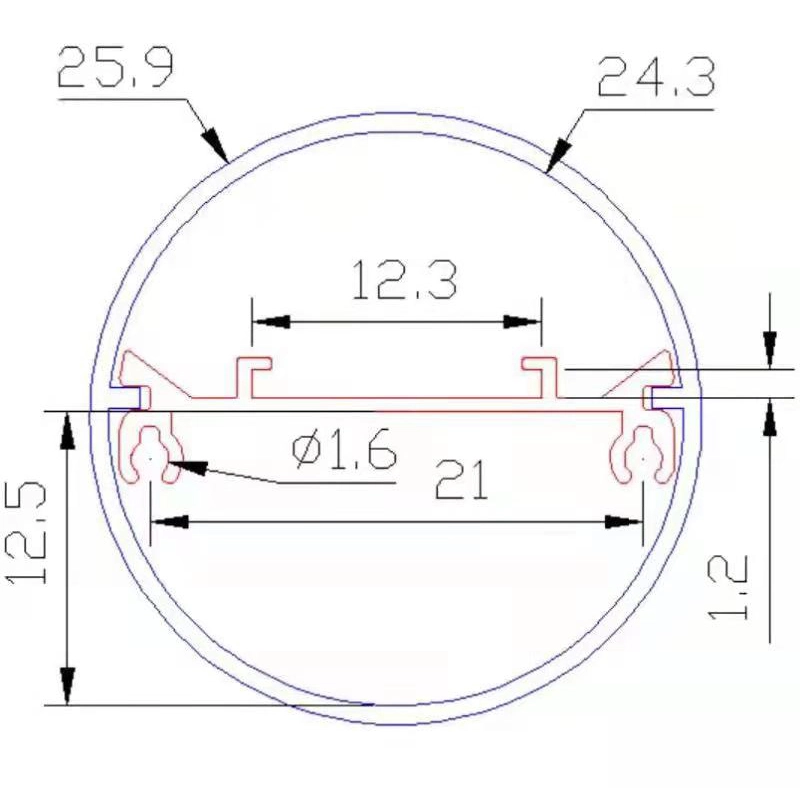

| Diameter | 26mm |

| PCB board size | 12*1mm |

| Driver | Internal |

| Max height of driver | 12mm |

| Aluminum profile inside material | 6063 aluminum alloy |

| Aluminum profile inside color | Silver |

| Plastic tube material | Plastic |

| Plastic tube color | White base, Frosted and Clear(transparent) cover |

| End caps | Plastic |

| Waterproof | IP20 or IP65 |

Product Feature And Application

This LED fly killer housing is mainly used for home lighting, shopping mall lighting, school lighting, parking lot lighting, and more.

Product Details

More details of this LED fly killer housing:

Product Qualification

As a LED Aluminum Profile and LED plastic profile professional manufacturer, here are our main machines:

1. 20 plastic extrusion machines

2. 5 aluminum extrusion machines,

3. A professional integrating sphere to test whether the lamps made by our lamp kit can meet the various indicators required by customers,

4. A professional standard light source testing equipment for testing the light transmittance and other properties of plastic lampshades.

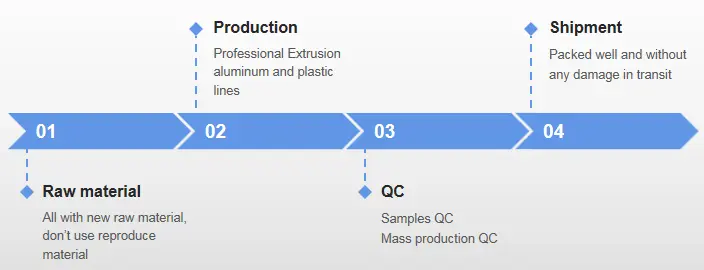

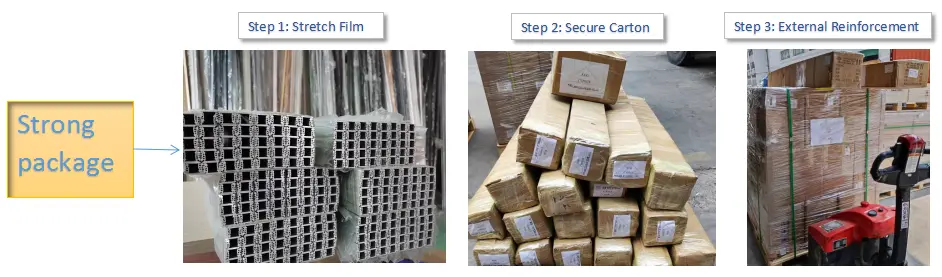

JE always focus on product qualification from aluminum and plastic raw material to extrusion production line, from samples quality control to mass production control, from strong perfect package to whole-heart service.

Deliver,Shipping And Serving

FAQ

Q1. What kinds of production can you manufacture?

Re: Regular and special-shapes extrusion aluminum and plastic profiles with different colors.

Q2. What kinds of LED lighting can use your profiles?

Re: LED cabinet lighting, LED strip lights, T5/T6/T8/T10/T12 tubes, tri-proof tubes and special-shape tubes, etc.

Q3. How many staffs in your factory?

Re: 50-80 staffs in production line. 8 staffs in sales team, 10 staffs in R&D.

Q4. How many machines in your factory?

Re: 20 of plastic extrusion production lines,

5 of aluminum extrusion production lines,

3 of injection molding machines,

5 of precision mold manufacturing equipment s,

2 of test equipment s(integrating sphere and Color Assessment Cabinet).

Q5. What is process of OEM order?

Re: Receiving drawing--Project manage confirm all production details with customer--Receiving tool production PO--Sales assistant proceed tool production--QC confirm samples are ready for shipping--Project manage confirm products with customer about every details-- start the regular order..