- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

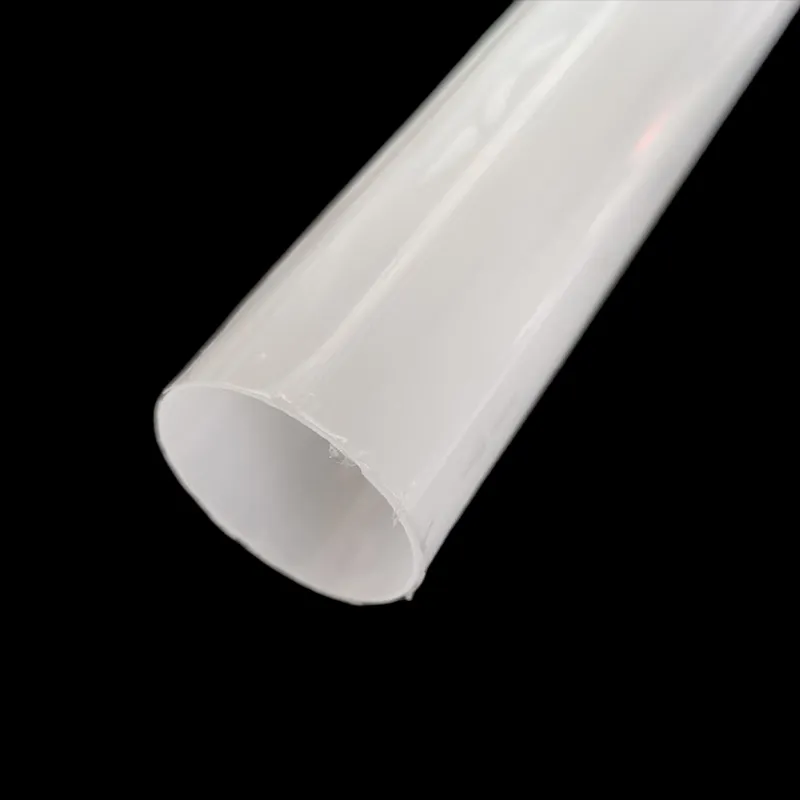

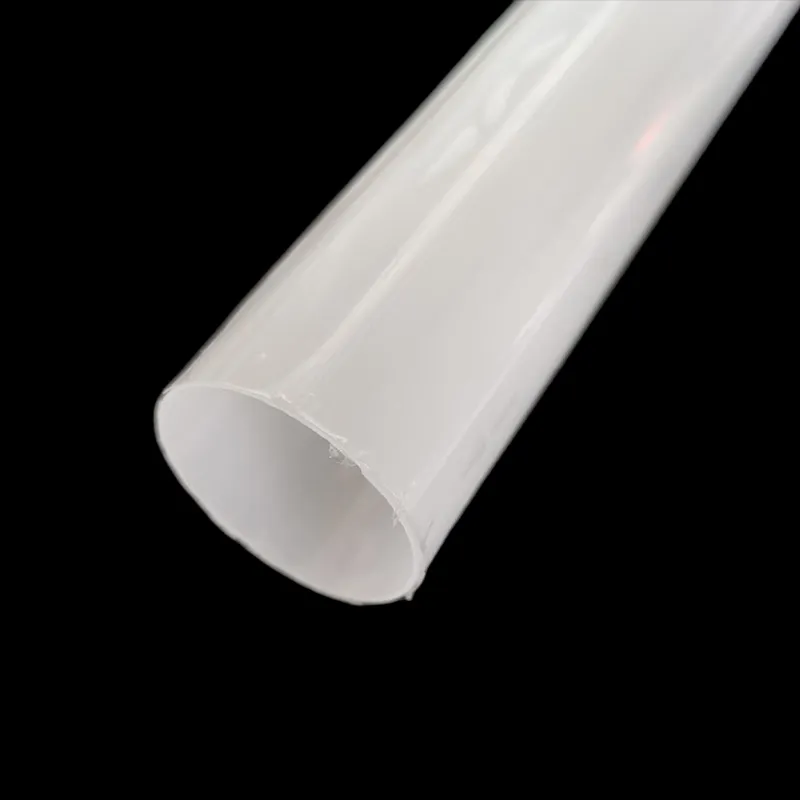

PC Diffuser

Since its establishment in 2017, JE Company has focused on the R&D, production, and manufacturing of PC diffusers for the lighting industry. Our company has independently developed and designed hundreds of PC diffuser products, which can be used for the production and modification of general lamp tubes, such as T5, T8, T10, and T12. They can also be used for the production and modification of lighting fixtures for specific applications, such as LED tri-proof lights, LED linear lights, and LED plant grow lights. In the lighting industry, light is the soul of a lamp. Besides the quality of LED chips and LED driver efficiency, the PC diffuser used on the LED housing is also crucial. Poor raw material quality will significantly reduce the light transmittance of the PC diffuser; poor manufacturing processes will affect the uniformity of light. Our company ensures the quality of our PC diffusers from the raw materials, and with years of production experience, we have elevated our PC diffuser manufacturing process to the forefront of the industry. These are the factors that earn our customers' trust. We welcome your inquiries.

Send Inquiry

Products Introduction

PC diffusers have been a core product of our company since we started manufacturing. We offer flexible solutions for this product category. For example: 1. If your project utilizes our existing lighting housings and PC diffusers, we will directly suggest suitable styles, lengths, and sizes. This allows for faster prototyping and production of new products, saving on customization costs associated with creating new molds. 2. If suitable housings and PC diffusers are not available in our existing lighting housings, we can provide design solutions and drawings for professional customization based on your requirements. 3. If you have your own design solutions and drawings, we can fully customize production according to your specific needs. Please don't worry about product quality; we insist on using 100% raw materials and strictly control the production process, resulting in products with a light transmittance of up to 95%. If you have projects requiring these materials, please feel free to contact us.

Product Parameter (Specification)

|

Item NO. |

JE-801 |

|

Outer Diameter |

4-400mm |

|

Length |

customized |

|

Wall Thickness |

0.4-5mm |

|

MOQ |

300KG |

|

Certification |

SGS, RoHS |

|

Raw material |

100% Pure polycarbonate |

|

Color |

Clear or customized |

|

Production technology |

Extrusion |

|

Package |

Protective Film, Carton |

Product Feature And Application

This PC tubes are widely used to advertise, indoor lighting, architecture, biological project, decorate, outdoor lighting, traffic lighting (train, subway), ambient light housings.

Product Qualification

As a LED Aluminum Profile and LED plastic profile professional manufacturer, JE always focus on product qualification from aluminum and plastic raw material to extrusion production line, from samples quality control to mass production control, from strong perfect package to whole-heart service.

Deliver,Shipping And Serving

FAQ

Q1. How long is the validity of the offer(quotation)?

Re: Usually for one month.

Q2. What kinds of LED lighting can use your profiles?

Re: LED cabinet lighting, LED strip lights, T5/T6/T8/T10/T12 tubes, tri-proof tubes and special-shape tubes, etc.

Q3. How many machines in your factory?

Re: 20 of plastic extrusion production lines,

5 of aluminum extrusion production lines,

3 of injection molding machines,

5 of precision mold manufacturing equipment s,

2 of test equipment s(integrating sphere and Color Assessment Cabinet).

Q4. How long is your lead time?

Re: For our regular items the lead time is about 3-5 days. For customized items, the lead time is about 25-35 days including tools making time.

Q5. What is your normal processes for regular order?

Re: We are very suggest customer give the forecast for the next three month. This are our normal processes for regular order:

Receiving PO--Sales confirm PI with customer--Receiving 30% payment in advance--Sales assistant proceed production and confirm the exact LT--QC confirm the goods are ready for shipping--Receiving the balance payment--Arranging shipment--after sales service.