- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

The Core Application Value of LED Tube Housings in Pest Control tubes

2025-09-04

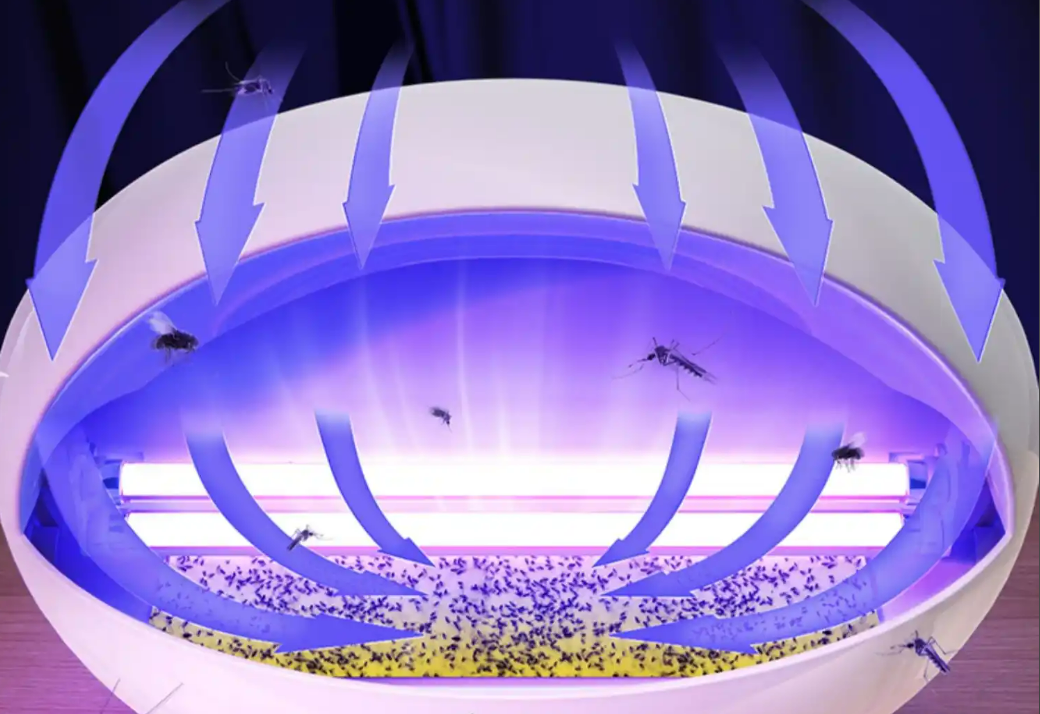

The LED tube housing (usually referring to its tubeshade or diffuser) plays a crucial and multifunctional role in insect control tubes, far more than simply providing protection and aesthetics. It directly impacts insect attraction efficiency, operational safety, product lifespan, and overall performance. The following is an analysis of its core application value:

1. Optical Control and Insect Attraction Efficiency (The Most Critical Role)

Transmission of Specific Wavelengths: The core of an insect control tube is the emission of ultraviolet light of a specific wavelength (typically around 365nm in the UVA band), which is the light source to which most pests (such as mosquitoes, flies, and moths) are most sensitive. The LED tube housing must have extremely high transmittance in this wavelength band to maximize the dissipation of UV energy and attract pests from a distance.

Light Diffusion and Uniformity: A high-quality housing (usually made of optical-grade PC or PMMA material with a special diffusion treatment) transforms the point light emitted by the internal LED beads into a uniform surface light source. This eliminates glare and dark areas, expands the effective insect attraction range, and allows pests to see the light source from all angles, thereby increasing the success rate of trapping.

2. Safety Protection (Dual Protection)

Internal Protection: Protects the delicate internal components, such as the LEDs, circuit boards, and high-voltage power grid, from dust, moisture, and insect corrosion. This is crucial for maintaining long-term stable operation.

External Protection: Preventing electric shock is paramount for human safety. The housing must completely isolate the internal high-voltage power grid (typically 3000V-5000V) to prevent accidental contact by users or pets.

Preventing Foreign Objects from Intruding: Provides excellent sealing (typically IPX4 (splashproof) or higher) to withstand complex outdoor weather conditions (such as rain and dew).

3. Structural Support and Heat Dissipation

Structural Integrity: The housing provides the structural framework for the entire product, securing all internal components and ensuring its robustness and durability.

Auxiliary Heat Dissipation: Although LEDs are inherently cold light sources, the high-power UVA LED chips and high-voltage power grid still generate heat during operation. Metal components (such as the end caps and internal brackets) and a well-designed plastic housing help conduct heat away, preventing excessive internal temperatures that could lead to accelerated light degradation or component damage.

4. Aesthetics and Cleanliness

Modern Design: The sleek exterior design blends seamlessly into various environments, such as homes, restaurants, and farms.

Easy to Clean: The smooth exterior surface allows for easy wiping to remove dust and insect debris, maintaining light transmittance and aesthetics.

JE is a factory specializing in the production of IP20/IP65 LED tube housing, for more tube housings, please refer to:

https://www.jeledprofile.com/led-tube-housing

For more details, please contact: sales@jeledprofile.com

Tel/Whatsapp/Wechat: 0086 13427851163