- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

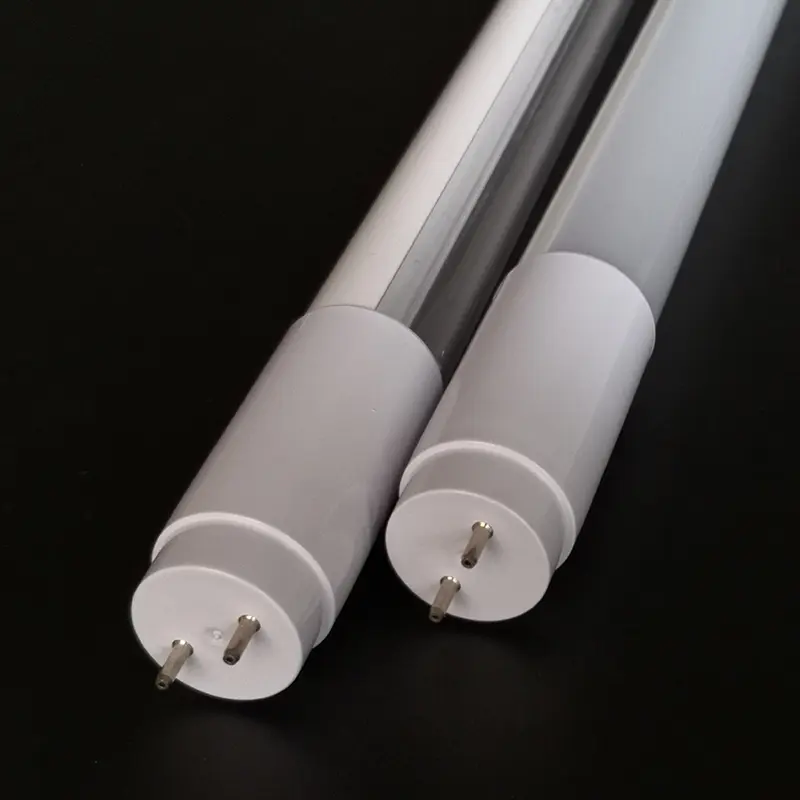

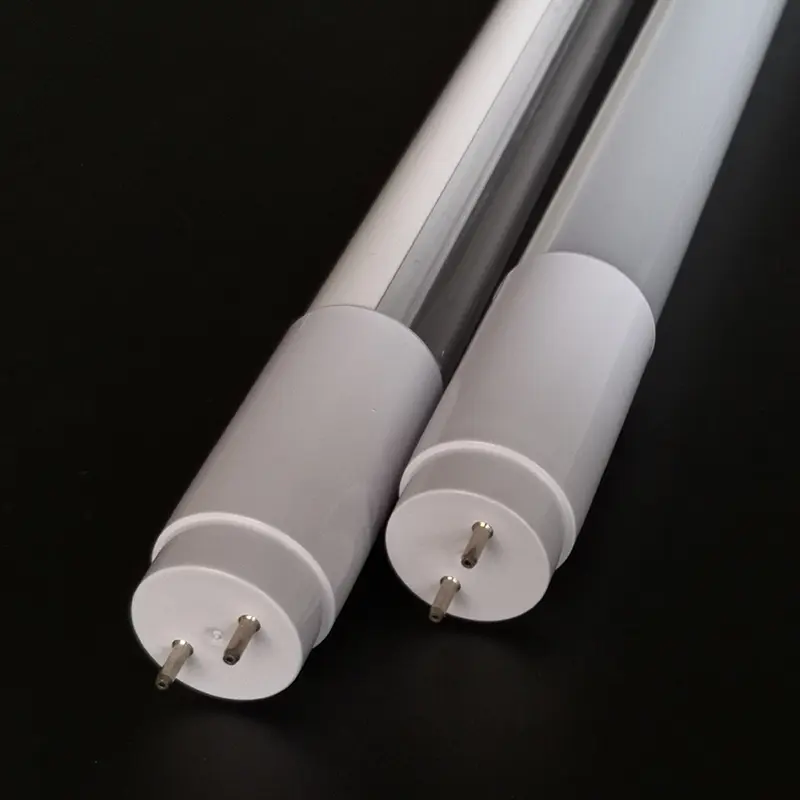

G13 T8 End Cap

JE is a professional LED tube end cap production and manufacturing factory with independent R&D team. We can develop various LED tube end caps according to market demand, including conventional end caps for LED T5/T8/T10/T12 tubes, as well as some end caps specially developed for special use environments, such as IP65 waterproof end caps with waterproof nuts and G13 T8 End Cap, which can make the tube waterproof. In addition, JE can also customize products according to customer needs. If you happen to have this need, please feel free to contact us.

Send Inquiry

This G13 T8 end cap is mainly suitable for lamps that need to have a built-in power supply but a large light-emitting surface. This length of end cap can be placed in the power supply and is completely invisible from the outside, which is both beautiful and practical. Both ends use G13 needles, and the lamp can be made into a single-end power supply or a double-end power supply.

Product Parameter (Specification)

|

Item NO. |

JE-EC09 |

|

Effective length |

42-50mm |

|

Tube |

T8 tube |

|

Material |

PC |

|

Color |

White |

|

Shape |

Round |

|

Pin |

G13 |

|

Wire |

With out wire/One wire |

|

Waterproof |

IP20 |

Product Feature And Application

G13 T8 end caps are mainly used in the production of LED tube replacement project, which are widely used in hotels, supermarkets, large shopping malls, parking lots, light box advertising, plant lighting, etc..

Product Details

More details of this G13 T8 end cap:

Product Qualification

Dongguan Jinen Lighting Technology Co., Ltd. is located in Dongguan City, Guangdong Province, the "world factory". The products we can produce include various special-shaped plastic profiles, PC round tubes for LED lighting, LED plastic tube diffusers, LED linear light housings, LED T5/T6/T8/T10/T12 tube housings, LED three-proof housings, LED LED aluminum profiles for light bars, etc. The materials we commonly process are PC, PMMA, ABS, PVC, etc. Most of the products are used in lighting, and some products are used in construction, decoration, packaging, toys, medical equipment and other industries.

As a LED tube housing manufacturer in China, JE has a professional design, development and production team for LED tube end caps, and can provide a variety of end caps matching LED tubes according to customer requirements,truly a one-stop shop type LED tube housing accessories supplier. The LED tube end cap is an important part of the LED tube housing. The production process is mainly injection molding, which can be used for LED T5 tube, LED T8 tube, LED T10 tube and LED T12 tube.

At present, the LED tube end caps produced by JE mainly include the following types: PC plastic tube end caps, aluminum-plastic combination end caps, locking screw end caps, step end caps, and integrated end caps. Some of these types can provide waterproof LED tube end caps with a waterproof coefficient of IP68, which are suitable for some professional lighting places, such as plant lighting, outdoor linear lighting, etc. The accessories of the LED tube end caps mainly include: T-type terminal wire, O-type terminal wire, plug inner plug, conductive copper sheet, stainless steel screw, hardened screw, power shell end cover, copper needle protection sleeve .

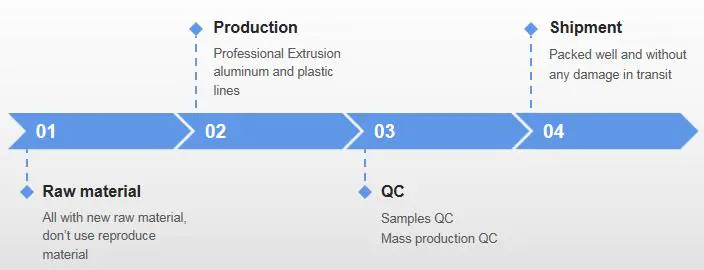

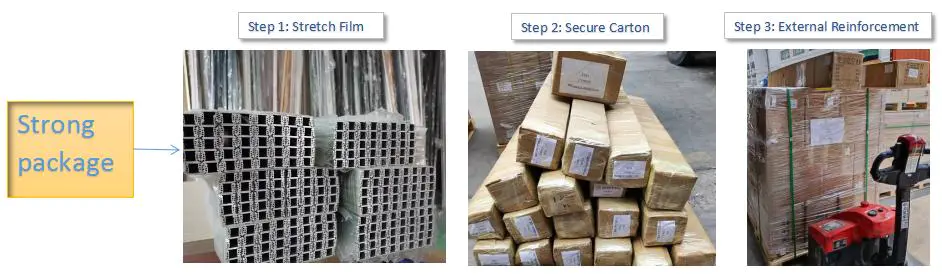

Deliver,Shipping And Serving

FAQ

Q1. Where is your factory located?

Re: We are located in “World manufacturer” Dongguan city, Guangdong province, China.

Q2. What kinds of LED lighting can use JE’s profiles?

Re: LED linear lights such as: LED cabinet lighting, LED strip lights, T5/T6/T8/T10/T12 tubes, tri-proof tubes and special-shape tubes, etc.

Q3. Is the mold opening cost borne by the customer or your factory?

Re: Customers pay the cost first, after the quantity is more than 50000 meters for total order, the tool cost can be deducted in order.

Q4. How many plastic extrusion production lines are in JE factory?

Re: We have 20 plastic extrusion production lines.

Q5. What is process of OEM order?

Re: Receiving drawing--Project manage confirm all production details with customer--Receiving tool production PO--Sales assistant proceed tool production--QC confirm samples are ready for shipping--Project manage confirm products with customer about every details-- start the regular order.